- Changchun Rongde Optics

- Co.,Ltd.

- Add:No.1666 Yaan Road,

- North Lake Development District,

- Changchun 130102,China

- Tel:86-431-81881745

- Fax:86-0431-85256892

- E-mail:rongdecui@roundss.net

- Skype:adacui_roundss

How to select, apply and integrate the right encoder for your industrial automation application.!

Changchun Rongde Optics Co.,Ltd. Release time:2016/3/26 Browse:896Encoders are used to determine the position, velocity and direction of motor shaft speed and other mechanical motion. They provide information required for the precise control of a variety of applications, such as positioning a rotary table, pick and place, machine assembly, packaging, robotics and more. Regardless of type, all encoders provide a type of orientation that’s used as a reference point for position control.

An encoder (for industrial controls) is a special sensor that captures position information and relays that data to other devices. The position information can be determined using one of three technologies: optical, magnetic or capacitive.

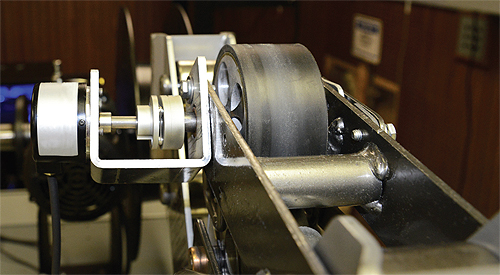

Optical encoders are the most accurate of the standard styles of encoders, and the most commonly used in industrial automation applications (Figure 1). When specifying an optical encoder, it’s important that the encoder has extra protection built in to prevent contamination from dust, vibration and other conditions common to industrial environments.

Figure 1. This optical rotary encoder is often used in industrial automation applications to sense rotary motion.

Magnetic encoders are more rugged than optical encoders, but have less resolution and accuracy. They are often used in environments with excessive dirt, steam, vibrations and other environmental factors that could interfere with optical encoder performance.

Capacitive encoders are relative newcomers to industrial automation. These encoders are as rugged as magnetic encoders, but also do not achieve the high resolution and accuracy of optical encoders.

Regardless of the sensing technology employed, the encoder’s electronics sense movement and translate that motion into industry-standard electrical signals.

Light duty, medium duty, and heavy duty are terms to differentiate encoders by indicating how much load can be applied to the shaft. A light duty encoder can handle some radial force on the shaft (for example, 10 N or 2.25 lbf); while a heavy duty encoder can accommodate much more radial force on the shaft (for example, 100 N or 22.5 lbf).

Environmental ratings also become more robust as the duty increases. Light-duty encoders are typically IP40 and IP50 (dust proof); whereas medium-duty and heavy-duty encoders are more rugged, and often rated up to IP65

Previous:Roundss Electonic Handwheel MPG Unit Postion Control Portable Encoder

Previous:Roundss Electonic Handwheel MPG Unit Postion Control Portable Encoder  Next:The output signals of incremental rotary encoders

Next:The output signals of incremental rotary encoders

Products

Products