Packaging & Delivery

| Packaging Details: | Carton |

|---|---|

| Delivery Detail: | 5 working days after payment |

| Packaging Details: | Carton |

|---|---|

| Delivery Detail: | 5 working days after payment |

1. Images of STS Hollow Shaft Optical Encoder 2048ppr CNC Spindle Encoder IP54

2. Features of STS Hollow Shaft Optical Encoder 2048ppr CNC Spindle Encoder IP54

1.Long life and saving cost.The Grating component of encoder is directly connected to lathe spindle without the aid of flexible couplings,flange and synchronous pulley,which saves the cost of mounting accessory.The bearingless non-contact design reduces the mechanical loss and ensures higher life.

2.Reliable performance.American original parts and chips, and integrated photoelectric switch module are adopted by STS series encoder to ensure stable and reliable quality.The disc with special material could resist high temperature and three times of vibration than regular encoder

3. Specifications of STS Hollow Shaft Optical Encoder 2048ppr CNC Spindle Encoder IP54

| Electrical Specifications | |

| Supply Voltage | DC5V±0.25V |

| Output Signal | Line Driver ( AM26C31) |

| Current Requirement | ≤80mA |

| Frequency Response | 100kHz |

| High-level Output Voltage | ≥2.5V |

| Low-level Output Voltage | ≤0.5V |

| Rise Time | ≤200 ns |

| Fall Time | ≤200 ns |

| Resolution | 1024 PPR |

| Mechanical Specifications | |

| Max. Speed | 10000 RPM |

| Radial Load (Max.) | 100N |

| Axial Load (Max.) | 50N |

| Starting Torque | 5X1O-3 N·m |

| Environmental Specifications | |

| Storage Temperature | -40℃- +80℃ |

| Operating Temperature | -30℃- +70℃ |

| Humidity | 30-85% (No condensation) |

| Protection Class | IP64 |

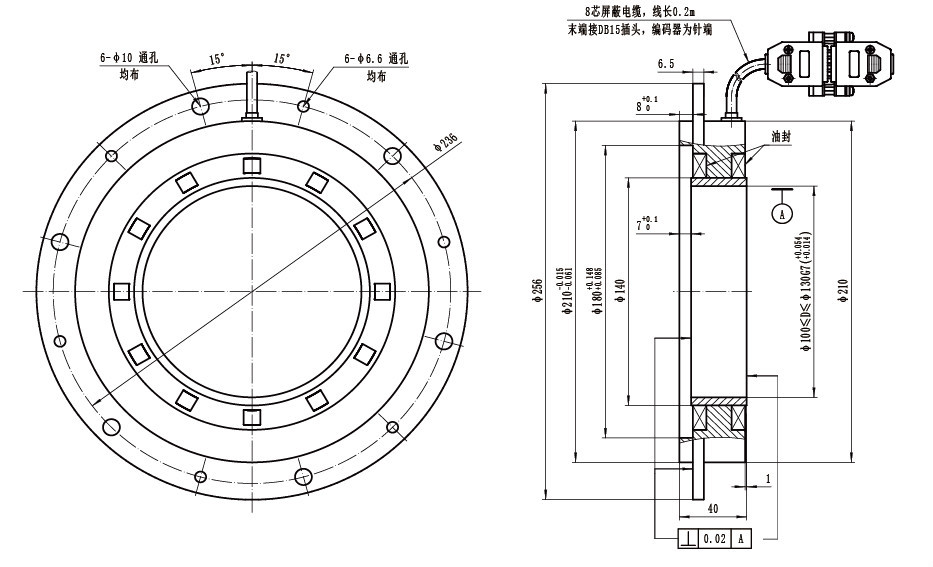

4. Mechanical Dimensions of STS Hollow Shaft Optical Encoder 2048ppr CNC Spindle Encoder IP54

5. Pre-sales Service of STS Hollow Shaft Optical Encoder 2048ppr CNC Spindle Encoder IP54

1.The hollow shaft rotary encoder can be customized to meet your need.

2.The questions about the encoder will be answered within 24 hours.

3.We have the best after-sale service.

Previous:NTD Magnetic Ring Encoder Optical Rotary Hollow Shaft Sensor

Previous:NTD Magnetic Ring Encoder Optical Rotary Hollow Shaft Sensor  Next:What is the difference between standard and high EMC grade?

Next:What is the difference between standard and high EMC grade?